The applications for flexible foams are limited only by one’s imagination.

Flexible Foams Overview

With 5 production facilities across the United States, American Excelsior provides “same source” locations close to major volume customer accounts, as well as offering smaller customers personalized service. Our foam fabricators have a wealth of industry knowledge and experience which they share with our customers every day – from reviewing blueprints to designing parts and developing prototypes.

AEC’s custom foam operations are used by a number of industries for a wide range of products, including, but not limited to: polyether foams for automotive door panels; polyester foams for government packaging; cross-link polyethylenes for protection in athletic equipment; high resilient foams for airport seating; and anti-static foams for packaging of sensitive computer equipment. The most common applications include athletic, automotive, furniture, electronics, marine, medical, novelty and packaging.

The longevity of our employees is also a valuable asset in the fabrication process. An employee who has worked in the same location for many years is intimately familiar with the parts we fabricate for our loyal customers. Whether it is open or closed-cell polyurethane or polyethylene, American Excelsior is well suited to address the needs of today’s cushioning and protection requirements.

In addition, if your company or customer is concerned about the environmental impact of flexible foams, our new Earth-Cell™ foam option may be the right choice for you.

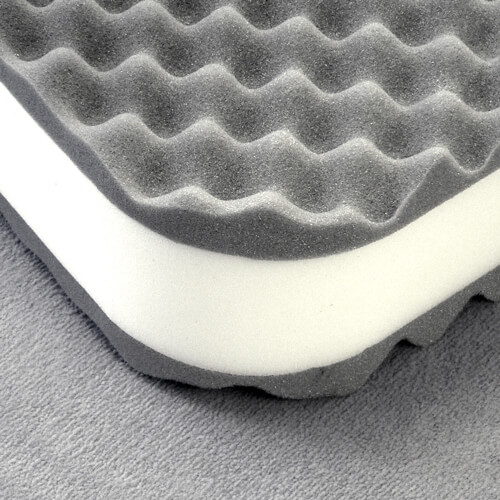

One of our newest offerings is a line of high-quality impact mats which were developed for use as medical floor mats, but which can be used in a variety of ways to reduce impact or fatigue. These mats are made using a unique dual-density process and have distinctive design, comfort and impact characteristics. We can also accommodate special orders to add your company name and/or logo to the mat. Contact us for more information.

Applications

Click an image to view Flexible Foam Applications flyers or scroll down to learn about other application.

|

|

|

|

|

|

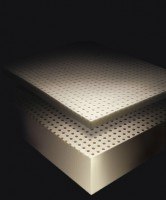

Packaging

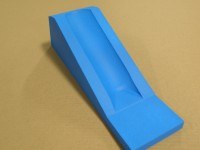

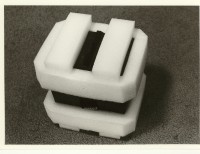

Case Inserts

American Excelsior provides flexible foam solutions for package & case inserts using a wide variety of flexible foams. In addition, our foams can be “flocked” or flame-laminated to give your insert a professional finished appearance of your product. Whether you are packaging a sensitive electronic instrument or producing a display package for retail, American Excelsior has a wide variety of flexible foams to meet your requirements. For more information please contact a representative in your area.

Dunnage & Protective Packaging

American Excelsior provides flexible foam solutions for dunnage and protective packaging and applications can be found in automotive returnable or non-returnable totes to surface protection of finished parts. For more information please contact a representative in your area.

Marine

Seating & Bedding

American Excelsior has been producing and designing flexible foam products for the marine industry since our early introduction of flexible foams back in the 1950’s and today, we are proud to say that we have business relations within the marine industry that go back 40 plus years and for one reason-they trust American Excelsior with their flexible foam requirements and they know that we will keep them abreast of new technologies and new products that will allow them to be the leaders in their market.

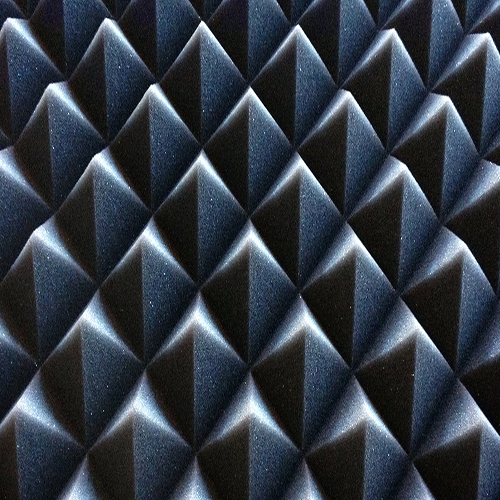

Insulation, Acoustical & Protection

In addition to marine seating and bedding foams, American Excelsior also provides flexible foam solutions for marine insulation, sound control and even foam protection pads to protect your vessel during transit. Foams can be laminated with secondary backings such as PSA adhesive to help hold in place or a reflective aluminized mylar film for heat reduction while providing additional light in engine compartments.

Flotation

As a customer of American Excelsior, you should always turn to us when you think of a flexible plastic product and foams for flotation are just another example of the many product offerings we have. In addition to flotation foams, American Excelsior can also design and manufacture closed-cell foams that are flame-laminated with a wide variety of fabrics which can be embossed or molded to give you a finished product such as a swim pad without the need of sewing.

Medical

Orthopedic

AEC is a recognized leader in flexible vinyl and elastomeric coatings for foam patient positioning, wheel chair seating, physical therapy products. With ongoing patient safety concerns regarding blood borne pathogens and other contaminants, it’s essential that these foam coatings provide a sealed, fluid proof, combustion modified, cleanable surface while offering patient comfort and pressure relief. Products used in radiology applications [x-ray, CT, MRI] also require a radiolucent or “noise free” coating that will not interfere with imaging. Our specialty coatings offer tremendous durability, flexibility and color choice. They can be applied to both our molded and fabricated foams. They provide a sealed, cleanable surface that is fluid and chemical resistant. The protective coatings can also be easily screen printed. We offer water base urethane and vinyl, non-flammable flexible coating to market and also offer low VOC coating technology.

Medical Seating

American Excelsior provides flexible foam solutions for medical seating, bedding or any application where patient comfort is desired. Our flexible foams can also be coated, flame-laminated with fabric, molded or made with secondary parts to help reduce your manufacturing process and provide a superior finished product.

Bedding

American Excelsior provides flexible foam solutions for medical bedding.

Packaging

American Excelsior provides flexible foam solutions for medical packaging.

Bedding

Mattresses

American Excelsior provides flexible foam solutions for bedding mattresses.

Novelty

Promotional Products

Flexible foams are used in many promotional type applications where bright colors and flexibility are required. Some of those applications include:

Foam Hats used to support your local charity or sporting event

Foam #1 Fingers as seen at sporting events

Foam cubes for jump pits

Foam toys such as building blocks, puzzles and other flexible type toys

The list goes on and on, so if your project requires a flexible foam product, American Excelsior probably has the foam to fit your need.

Industrial

Furniture

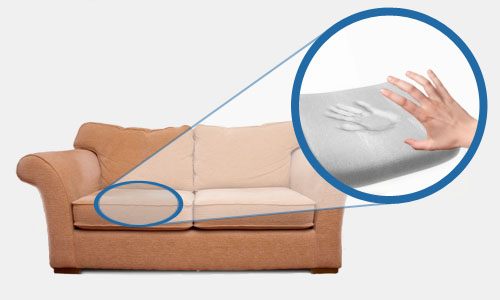

Sofa / Chair Cushions

American Excelsior provides a wide variety of flexible foam products for use in furniture cushions, chairs, arm rests, back cushions or anywhere when comfort or a plush look is needed. Our product offering covers a vast range of products to assure that the performance and value of your finished product is being met. We have been fabricating flexible foams for the furniture and seating industry for over 50 years and our customers value us a partner in the success of their product and our people are willing to work your upholstery teams to better understand the performance of your finished product so they can assist you in the right choice of foams.

Packaging

In addition to providing flexible foams for cushioning in chairs and sofa’s, American Excelsior provides flexible foams for the protection of your finished furniture. This includes Amcel polyethylene foam sheets or rolls available from 1/32″ to 1/2″, all the way to PE plank fabrication for heavy bracing of your finished product for shipment. If it’s comfort or protection, we can design the right product for the right application.

Automotive

Packaging & Protection

American Excelsior provides flexible foam solutions for automotive sound dampening, vibration control or in areas where reductions of noise is needed due to moving parts or outside interference. Most foams can be laminated with secondary products such as PSA adhesive, Mylar films or other products to meet the demands of the application.

Acoustical & Vibration

Recreational / Athletic

Body Protection

Flexible foams have become the product of choice when it comes to protection cushioning in the athletic/recreational industry, but you need to be selective of that choice since there are so many products on the market all claiming to meet performance standards of some degree. For that reason, you should know and understand what those claims are so you can make the right foam choice for your finished product. With a wide variety of polyurethane, Polyethylene and cross-links foams, we can “design product neutral”, meaning we fit the right foam to the right application. Not try and and fit a particular foam to all applications just because we are limited in our product offering.

In addition to custom fabrication, American Excelsior can also mold, flame-laminate and provide a special process where fabrics are laminated to foam and then compression molded to give you a finished part. In many cases, this unique process can reduce or eliminate sewing or other secondary operations to your finished product.

Display

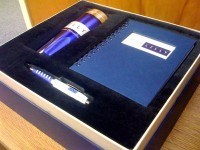

Foam with Flocking

Flocked foams provides the feel and appearance of velvet on your foam and is great for display applications and it great for those times when you want to impress your customer and highlight the item being packaged or displayed. Great for promotional items, glassware, trophies, coins, pen and pencil sets and many more applications. For a sample of this material, contact your local American Excelsior office or call: (800) 326-FOAM.

Excelsior Wood Fibers

American Excelsior supplies excelsior wood fiber products to diverse markets for a wide variety of applications. From baled excelsior to aspen animal bedding to evaporative cooler pads, wood excelsior products have an almost endless list of applications. We offer more than 50 different cuts of excelsior fibers to meet even the most specialized applications.

American Excelsior supplies excelsior wood fiber products to diverse markets for a wide variety of applications. From baled excelsior to aspen animal bedding to evaporative cooler pads, wood excelsior products have an almost endless list of applications. We offer more than 50 different cuts of excelsior fibers to meet even the most specialized applications.

We use Great Lakes, all-natural Aspen, as a wood source for all of our wood excelsior products. We purchase Aspen only from forest products companies that are members of the Sustainable Forestry Initiative program. This ensures that our vendors are following the best environmental and forestry management practices. We are proud of our environmental stewardship commitment.

Natural excelsior boxed excelsior and baled excelsior are offered for use in specialized packaging for retail outlets. Excelsior is easy to work with, safe, and 100% biodegradable. It is a favorite when used in wreaths, garlands, and fruit and gift boxes or baskets. Excelsior fibers may be shaped, sized, glued, molded, matted, or woven to fit numerous decorative applications.

In the packaging industry, wood excelsior is an ideal product to protect and cushion larger, heavier, or more irregularly shaped products (e.g. heavy parts or statuary products). The unique, curled excelsior fibers have a barbing feature that enables the fibers to interlock and provide excellent packing and packaged cushioning capabilities not found with other types of packaging materials. Furthermore, excelsior is biodegradable making it an environmentally safe product. For protecting smaller and lighter fragile products, such as china, glassware, and pottery products, our Curlex® packaging pads feature excelsior fibers encapsulated in the paper for natural cushioning.

Wood excelsior fibers are also widely used as a filtration medium, ranging from filtering oil in combustion engines to oil field filtering and vinegar filtration. The interlocking, barbing features of the fibers, combined with low moisture content from air curing, results in highly absorbent fibers capable of filtering without any artificial additives. In the construction industry, excelsior is frequently used in tunneling and pipe installations to fill void areas.

Other applications for wood excelsior fiber products include, among other things, use in ceiling boards, taxidermy, burn blocks at fire training schools, concrete extenders, oil booms, pipeline padding, and snake bedding.

We invite you to browse our wood fiber site to learn more about our products and contact us at sales@americanexcelsior.com with any questions or call 866-934-2377 (Toll-Free). Our Customer Care personnel will work with you to select the excelsior product best suited for your needs.

Cosmetics

Specialty Uses

Resources

FAQs

Are there any foams on the market that are considered environmentally-friendly?

Yes! There are flexible foams on the market that are made using non-oil based chemicals such as soy, and American Excelsior has a wide variety of optional “green” foams marketed as Earth-Cell™.

What is a board foot?

A board foot (b/f) is the industry standard for pricing flexible foam and is basically the same method used in the lumber industry to calulate wood. One board foot is: 12″ x 12″ x 1″. To calulate the number of board feet, simply take the length x width x thickness and divide by 144. Example: A 24″ x 24″ x 4″ piece of foam has 16 board feet.

What does IFD stand for?

Indentation Force Deflection which is a measure of the load bearing capacity of flexible polyurethane foam. IFD is generally measured as the force (in pounds) needed to compress a 50 square inch circular indent or foot into a 4″ thick sample, typically 15″ squarer, to a stated percentage of the sample’s initial height. Lower number ratings such as 15#-20# is soft and generally used for back or pillow type applications. The higher the number, the firmer the foam will be. Also used to be called “ILD (Indentation Load Deflection)”.

What does the “density” of foam mean?

Density is the measurement of the mass per unit volume and it is measured in pounds per cubic foot. Density is sometimes confused with the firmness of a foam. If you took a 12″ x 12″ x 12″ block (1 cu/ft) of a foam that is supposed to be a 1.8# density, it should weigh 1.8# with a normal tolerance of plus/minus .5#.

What does “reticulated foam” mean?

A Reticulated Foam is characterized by a three-dimensional skeletal structure with few or no membranes between strands. Reticulated foams are generally used as filters, acoustical panels, and for controlled liquid delivery. Reticulated foams are sometimes referred to as “filter foams”.

What does TDI stand for?

Abbreviation for toluene diioscyanate, a chemical used in the production of polyurethane foams.

Is there an easy way to cut foam at home?

Yes- Using normal safety precautions when cutting, an electric kitchen knife works quite well on most foams.

Technical Support

To view PDF documents, you may [download the free Reader from Adobe ]

American Excelsior understands your need for flexible foam documentation & specifications. This documentation is being gathered for this new web page. Until then, for more information please contact a representative in your area.

Material Specifications

Product Descriptions

Amexcoat Product Sheet.pdf 6 MB

Dual Density Medical Mat.pdf 810 kB

Earth-Cell Foam Products Sheet.pdf 1.31 MB

Viscool Sale Sheet.pdf 224 kB

SDS

Amcel Polyethylene Foam SDS.pdf 198 kB

Crosslink Foam SDS.pdf 131 kB

Dual Density Mat SDS 138 kB

Molded Polyurethane Foam SDS.pdf 213 kB

Polypropylene Foam SDS.pdf 196 kB

Polyurethane Foam SDS.pdf 283 kB

Contact

We believe in personal and professional attention to our customers and that is why during business hours, we have intelligent, enthusiastic, living human beings answering the phone. If you tell them what you want, they will either provide you with the information you need or will direct you to someone who can.

Flexible Foam Sales Representatives

Phone: 1-888-352-9582

Fax: 1-888-352-9585

John Bosch: Division Director — 412.721.1270

Kevin Coakley: 262.751.1421 — ND, SD, NE, MN, WI, IA,

Bill Edwards: 817.319.0620 — AZ, CO, NM, KS, OK, TX, AR, LA, MS, AL, GA, FL

Bill Kehoe: 216.744.5765 — MI, OH, KY, TN, ME, VE, NH, MA, RI, CT, NY, PN, NJ, DE, MD, WV, VA, NC, SC

Jeff Schlect: 509.969.4472 — WA, ID, MT, WY, CA

Kim Cripe: 206-795-3181 — WA, OR, NV, UT

Jamie Wellemeyer: 630.284.5202 — IA, MO, IL, IN, KY, TN

Gordy Zastrow: 920.242.3254 — MN, WI