American Excelsior Company—the inventor of the Curlex® brand and biodegradable erosion control blankets—has been the most trusted name in erosion control since the 1960s.

Erosion Control Overview

Have you ever wondered why Curlex® is so popular?

If so, find out by viewing our Curlex Features and Benefits document.

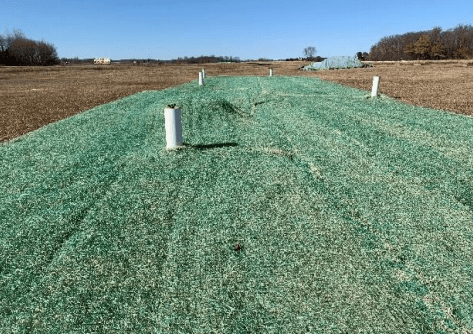

Rolled Erosion Control Products (RECPs) are fibrous products, manufactured out of either natural materials (e.g. Curlex® aspen excelsior wood fibers, straw and coconut fiber), synthetic materials (e.g. polyester) or a mixture of natural and synthetic materials. Erosion Control Blankets (ECBs) are degradable RECPs and Turf Reinforcement Mats (TRMs) are RECPs that contain synthetic components. RECPs are used primarily to slow water runoff, provide effective sediment and erosion control, and enhance re-vegetation. These products are commonly applied to channel and ditch linings, slopes, culvert inlets and outfalls, riverbanks, and levees amongst many other applications.

RECPs are classified as short term, long term, or TRMs. Sediment Control Products assist when soil particles become entrained in runoff.

American Excelsior offers a wide variety of erosion control blankets under the Curlex® brand and other specialized products, like the QuickGRASS® Pro, to meet a plethora of needs.

View Our Product Brochures

Short-Term Erosion Control Blankets

The Original Curlex® Erosion Control Blanket

Designed using cuts of Great Lakes aspen fibers, these blankets were developed in the early 1960s to provide ideal conditions for grass seed growth, while simultaneously shielding the topsoil from water and wind erosion. These blankets also have a built-in swell factor, which allows the fibers to expand and form a stronger matrix when wet.

Curlex® CL Blankets

A cheaper, lighter version of the original Curlex Erosion Control Blanket®, this blanket promotes superior vegetation establishment support when compared to straight-lined fiber blankets (e.g. straw).

AEC Premier Straw® Blankets

Top quality agricultural straw fibers, which are certified weed seed free, are stitched in single or double netting to the top side or on both sides of the erosion control blanket.

Curlex® NetFree™ Blankets

A 100% biodegradable erosion control blanket made from sturdy, interlocking, curled and barbed Great Lakes aspen fibers which require no netting to support the structure, resulting in little to no incidences of tripping and animal trapping.

Long-Term Erosion Control Blankets

Curlex® Double Net (Curlex® II)

An organic, consistently thick, specific cut of Great Lakes Aspen curled wood excelsior with at 80% of six inches or greater fiber length.

Curlex® III

Made from Great Lakes Aspen excelsior fibers, these blankets encourage ideal growing conditions and provide seed and topsoil protection for up to 36 months.

AEC Premier Coconut™

Made from the finest quality strands of coconut fiber, this erosion control blanket is stitched together using a special UV-enhanced heavy black net on top and bottom.

AEC Premier Straw/Coconut™ Blankets

70% of the finest quality weed seed-free agricultural straw and 30% top quality strands of coconut fiber are intertwined and evenly distributed in the erosion control blanket and stitched with a UV-enhanced black net on top and a UV-enhanced green net on the bottom.

Turf Reinforcement Mats (TRMs)

Permanent turf reinforcement mats, for long-term protection against wind and water erosion, are a natural choice in place of stone or riprap in swales, ditch bottoms, and on long, steep slopes.

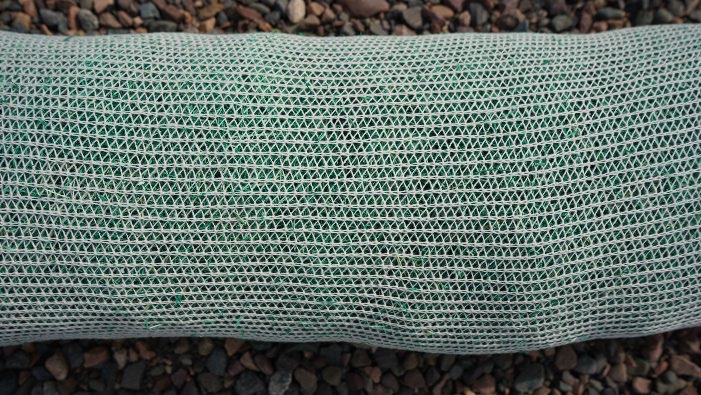

TriNet® Family of TRMs

TriNet® Family of TRMs: Three-netted heavy-duty TRMs for permanent protection in critical areas where vegetation alone requires extra protection from shear stress forces.

Curlex® Enforcer®

A bio-composite turf reinforcement mat designed for service of at least 36 months or more, this erosion control blanket is made from naturally seed-free Great Lakes Aspen excelsior fibers bound by 2 layers of extra heavy-duty black UV-enhanced netting to ensure permanent reinforcement between root systems and the established vegetation.

Recyclex® TRM and Recyclex® TRM-V

The first environmentally responsible turf reinforcement mat made from 100% recycled post-consumer goods designed to meet the most difficult erosion and sediment control challenges.

Sediment Control Devices

Curlex® Bloc

A naturally seed-free and nontoxic alternative to coir logs, these Blocs are high-density, natural filters designed to start degrading during the first year of its 3-year lifespan to allow seed and sediment into the Curlex fiber matrix.

AEC Premier Straw® Wattles

Made from certified weed-seed-free straw fibers, the dense nature of the finest quality agricultural straw fibers encased in durable netting allows water to pool instead of filtering through.

Curlex® Hi-Vis Excelsior Logs

Curlex Hi‐Vis Excelsior Logs are easy to move with their durable handles. But, the best part of them is what you don’t see. These are the only high‐visibility logs filled with the naturally seed‐free Great Lakes Aspen Curlex fibers that you know and trust.

Curlex® Sediment Log®

Designed to reduce the velocity of flowing water and filter out sediment, these environmentally-friendly, degradable sediment logs are made up of intricate, interlocked fiber log matrices.

Curlex® SiltTRAP™

A temporary buffer strip that offers a unique way of trapping and capturing sediment before it is washed away, filling gutters and clogging pipes. The naturally seed-free SiltTRAP™ fibers filter soil from the runoff and offer a mess-free alternative to silt fences.

Products

View Our Product Brochures

View Product Brochure View Anchor & Staple Brochure

- 100% Biodegradable Erosion Control Options

- AEC Premier Straw/Coconut™ & AEC Premier Coconut™

- AEC Premier Straw®

- Bindex™ BFM

- Bindex Wood / Excel® Fibermulch II

- Curlex® I and II Blankets

- Curlex® Bloc, an American-Made Alternative to Coir Logs

- Curlex® CL Blankets

- Curlex® Enforcer® TRM

- Curlex® Green Savers™

- Curlex® III and High Velocity HD Blankets

- Curlex® Hi-Vis Excelsior Logs

- Curlex® NetFree™

- Curlex® RoadRunner™

- Curlex® Sediment Log®

- Curlex® Septic Blankets

- Curlex® SFW Wattles

- Curlex® SiltTRAP™

- Eco-Sustainable™ Products

- E-Staple®

- QuickGRASS®PRO Erosion Blanket

- Recyclex® TRM and Recyclex® TRM-V

- TriNet® Family of TRMs

Applications

Utility Transmission Right-Of-Way

Challenge

Post construction land restoration at remote sites

Goal

Environmental remediation after utility construction

Solution

Use our products for EPA/NPDES compliance

Benefit

Faster re-vegetation of natural landscape

Residential Development

Challenge

Protect topsoil & grass seed in common and residential areas

Goal

Provide BMPs to aid the developer in complying with Phase I and Phase II sediment retention regulations

Solution

Keep topsoil in place, contain sediment, provide aesthetics and enhance germination

Benefit

A perfect system for keeping sediment out of inlets and storm drains, while providing erosion protection in swales and around pond slopes

Commercial Development

Challenge

Control runoff and sheet flow from parking lots and paved areas

Goal

Provide BMPs to meet NPDES Phase I and Phase II soil retention regulations

Solution

Use our products to keep top soil in place after final grading

Benefit

Protect topsoil, grass seed, and enhance revegetation

Highway Construction

Challenge

Protect topsoil in ditch bottoms, medians, side slopes, waterways, and outlets

Goal

Meet FHWA and State highway regulations

Solution

Use Curlex® RoadRunner™ installation system to maximize labor savings while minimizing crew size

Benefit

A quicker return of a natural landscape right-of-way

Golf Course Construction

Challenge

Soil retention and revegetation after final grading

Goal

Use Curlex® products to protect topsoil from wind and water erosion, while promoting ideal growing conditions for grass seed in fairways, around greens, roughs and waterways

Solution

Use our products to prevent regrading due to erosion

Benefit

Enhance germination process to expedite the opening of your course

Slope Stabilization

Challenge

Minimize erosion and maximize revegetation on steep slopes

Goal

Protect real estate developments

Solution

Erosion control blankets made of excelsior fibers to fight erosion

Benefit

Panoramic aesthetics are enhanced and threat of major soil loss is minimized

Landfill Development

Challenge

Protect topsoil on caps, side slopes, down-chutes, and perimeter waterways

Goal

To meet regulatory compliance and landfill aesthetics

Solution

Create “best management” practices for on-site water management

Benefit

Projects will meet or exceed BMP standards for engineering excellence

Urban Drainage

Challenge

Protect urban areas from streams that fill quickly with storm water

Goal

Stabilize valuable real estate and improve urban environment

Solution

Create a systems approach for the elimination of stream scour and stabilize stream banks

Benefit

Reduce potential damage associated with heavy rainfall and enhance urban living

Workshops

THE INVENTORS OF CURLEX®, THE MOST TRUSTED NAME IN THE EROSION AND SEDIMENT CONTROL INDUSTRY, PRESENT:

Lunch & Learn Workshops

Here’s just a sampling of what you will get from the luncheon workshop:

- The different fiber types being used in erosion control blankets (straw, coconut, wood/Curlex®)

- Temporary erosion control blankets (ECBs) vs. permanent turf reinforcement mats (TRMs)

- How netting options affect longevity and slope effectiveness

- Different strategies for dealing with erosion vs. sediment control

- NPDES stormwater compliance tips for your projects

- Innovative erosion analysis and design software

- 1 PDU and training certificate available for all attendees

Complete the form below to enter your request for a Lunch and Learn Workshop. A representative of American Excelsior Company will contact you quickly to set a luncheon date and discuss your Lunch and Learn Workshop.

Resources

Technical Support

View Our Product Brochures

View Product Brochure View Anchor & Staple Brochure

To download a CAD.dwg file, please right-click on the .dwg file in order to Save Link As… to your desktop folder for your personal use.

CAD Details

AEC Premier Coconut Channel CAD.pdf 167 kB

AEC Premier Coconut Channel CAD.dwg 167 kB

AEC Premier Coconut Slope CAD.pdf 132 kB

AEC Premier Coconut Slope CAD.dwg 550 kB

AEC Premier Straw Channel CAD.pdf 164 kB

AEC Premier Straw Channel CAD.dwg 498 kB

AEC Premier Straw Slope CAD.pdf 131 kB

AEC Premier Straw Slope CAD.dwg 427 kB

AEC Premier Straw/Coconut Channel CAD.pdf 167 kB

AEC Premier Straw/Coconut Channel CAD.dwg 577 kB

AEC Premier Straw/Coconut Slope CAD.pdf 132 kB

AEC Premier Straw/Coconut Slope CAD.dwg 541 kB

AEC Premier Straw Wattles Slope Interruption CAD.pdf 87.9 kB

AEC Premier Straw Wattles Slope Interruption CAD.dwg 314 kB

Bindex BFM Slope CAD.pdf 453 kB

Bindex BFM Slope CAD.dwg 538 kB

Curlex Bloc Anchoring Techniques CAD.pdf 392 kB

Curlex Bloc Anchoring Techniques CAD.dwg 1MB

Curlex Bloc Filtration CAD Part 1.pdf 132 kB

Curlex Bloc Filtration CAD Part 1.dwg 1 MB

Curlex Bloc Filtration CAD Part 2.pdf 146 kB

Curlex Bloc Filtration CAD Part 2.dwg 1 MB

Curlex Bloc Shoreline CAD.pdf 516 kB

Curlex Bloc Shoreline CAD.dwg 1 MB

Curlex Bloc Dewatering Structure Sheet.pdf 121 kB

Curlex Bloc Dewatering Structure Sheet.dwg

Curlex Channel CAD.pdf 165 kB

Curlex Channel CAD.dwg 585 kB

Curlex CL Channel CAD.pdf 559 kB

Curlex CL Channel CAD.dwg 1 MB

Curlex CL Slope CAD.pdf 520 kB

Curlex CL Slope CAD.dwg 1 MB

Curlex Dewatering Structure.pdf 119 kB

Curlex Dewatering Structure.dwg 780 kB

Curlex Enforcer Channel CAD.pdf

Curlex Enforcer Channel CAD.dwg

Curlex Enforcer Slope CAD.pdf

Curlex Enforcer Slope CAD.dwg

Curlex Hi-Vis Log Channel CAD.pdf 167kB

Curlex Hi-Vis Log Channel CAD.dwg 907 kB

Curlex Hi-Vis Log Inlet Protection CAD.pdf 120 kB

Curlex Hi-Vis Log Inlet Protection.dwg 652 kB

Curlex Hi-Vis Log Single Perimeter Control CAD.pdf 101kB

Curlex Hi-Vis Log Single Perimeter Control CAD.dwg 645 kB

Curlex Hi-Vis Log Slope Interruption CAD.pdf 135kB

Curlex Hi-Vis Log Slope Interruption CAD.dwg 838 kB

Curlex Hi-Vis Log Stacked Installation CAD.pdf 167 kB

Curlex Hi-Vis Log Stacked Installation CAD.dwg 1MB

Curlex Hi-Vis Log Triple Stack Perimeter Control CAD.pdf 130 kB

Curlex Hi-Vis Log Triple Stack Perimeter Control CAD.dwg 1 MB

Curlex NetFree Channel CAD.pdf 145 kB

Curlex NetFree Channel CAD.dwg 697 kB

Curlex NetFree Slope CAD.pdf 118 kB

Curlex NetFree Slope CAD.dwg 674 kB

Curlex Sediment Log Bio Channel CAD.pdf 124 kB

Curlex Sediment Log Bio Channel CAD.dwg 887 kB

Curlex Sediment Log Bio Inlet Protection CAD.pdf 95 kB

Curlex Sediment Log Bio Inlet Protection CAD.dwg 644 kB

Curlex Sediment Log Bio Perimeter Control CAD.pdf 111 kB

Curlex Sediment Log Bio Perimeter Control CAD.dwg 653 kB

Curlex Sediment Log Bio Slope Interruption CAD.pdf 100 kB

Curlex Sediment Log Bio Slope Interruption CAD.dwg 823 kB

Curlex Sediment Log Bio Stacked Installation.pdf 160 kB

Curlex Sediment Log Bio Stacked Installation.dwg 1MB

Curlex Sediment Log Channel CAD.pdf 159 kB

Curlex Sediment Log Channel CAD.dwg 466 kB

Curlex Sediment Log Inlet Protection CAD.pdf 112 kB

Curlex Sediment Log Inlet Protection CAD.dwg 383 kB

Curlex Sediment Log Perimeter Control CAD Part 1.pdf 125 kB

Curlex Sediment Log Perimeter Control CAD Part 1.dwg 523 kB

Curlex Sediment Log Perimeter Control CAD Part 2.pdf 100 kB

Curlex Sediment Log Perimeter Control CAD Part 2.dwg 506 kB

Curlex Sediment Log Slanted Stakes CAD.pdf 174 kB

Curlex Sediment Log Slanted Stakes CAD.dwg 639 kB

Curlex Sediment Log Slope Interruption CAD.pdf 125 kB

Curlex Sediment Log Slope Interruption CAD.dwg 490 kB

Curlex Sediment Log Stacked Installation CAD.pdf 166 kB

Curlex Sediment Log Stacked Installation CAD.dwg 1MB

Curlex SFW Slope CAD.pdf

Curlex SFW Slope CAD.dwg

Curlex SiltTrap CAD.pdf 62.7 kB

Curlex SiltTrap CAD.dwg 348 kB

Curlex Slope CAD.pdf 138 kB

Curlex Slope CAD.dwg 433 kB

Recyclex Channel CAD.pdf 163 kB

Recyclex Channel CAD.dwg 518 kB

Recyclex Curlex Shoreline Double Layer Protection CAD.pdf 121 kB

Recyclex Curlex Shoreline Double Layer Protection CAD.dwg 204 kB

Recyclex Curlex Shoreline Single Layer Protection CAD.pdf 103 kB

Recyclex Curlex Shoreline Single Layer Protection CAD.dwg 194 kB

Recyclex Slope CAD.pdf 129 kB

Recyclex Slope CAD.dwg 915 kB

Solar Panel Array Erosion Control AEC CAD.pdf 165 kB

Solar Panel Array Erosion Control AEC CAD.dwg 448 kB

TriNet Coconut Channel CAD.pdf 149 kB

TriNet Coconut Channel CAD.dwg 790 kB

TriNet Coconut Slope CAD.pdf 125 kB

TriNet Coconut Slope CAD.dwg 774 kB

TriNet Curlex Channel CAD.pdf 148 kB

TriNet Curlex Channel CAD.dwg 789 kB

TriNet Curlex Slope CAD.pdf 130 kB

TriNet Curlex Slope CAD.dwg 775 kB

TriNet Recyclex Channel CAD.pdf 151 kB

TriNet Recyclex Channel CAD.dwg 697 kB

TriNet Recyclex Slope CAD.pdf 125 kB

TriNet Recyclex Slope CAD.dwg 780 kB

TriNet Straw/Coconut Channel CAD.pdf 149 kB

TriNet Straw/Coconut Channel CAD.dwg 687 kB

TriNet Straw/Coconut Slope CAD.pdf 130 kB

TriNet Straw/Coconut Slope CAD.dwg 773 kB

Case Studies

Addressing Stormwater, Sediment Control and Safety with Curlex Hi-Vis Excelsior Logs

Advancing Erosion Control Anchor Technology

Almost Schooled by the Florida Pan Handle Soils—Curlex II

An Innovative Solution to Golf Course Erosion—Curlex NetFree

Bringing Green Roofs to Life with Curlex

Channel Erosion Done Right – Avoiding the Race to the Bottom

Colorado Open Space Berm Project—AEC Premier Coconut

Community Comes Together—Curlex NetFree, Enforcer, Sediment Logs

Curlex Bloc Case Study of Wetland Mitigation Bank in Clarion, IA

Curlex Helps Put a Cap on Landfill Erosion

Curlex NetFree Onion River Trout Unlimited

Curlex Proves Superior Over Straw at Laurel Park Landfill

Curlex Scores Hole-in-One at TPC Golf Course

Curlex to TriNet Curlex – A Case History

Curlex Wetland Mitigation

Dam or Filter—Curlex Sediment Log

Enforcing Soil in Place—Curlex Enforcer

Fire and Ice – Curlex in Extreme Climates

Freedom Park Stream Restoration Project Repair—Curlex NetFree

Highway Right-of-Way Solution is Curlex

New Restaurant Goes Topless and Bottomless—Curlex NetFree

Pikes Peak Erosion Solutions

Protecting Landfills With RECPs—Curlex

Protecting Sensitive Water Resources with Curlex II

Quarry Reclamation with All-Natural Curlex ECBs

Reclaiming Mines With Recycled Materials—Recyclex TRM

Recyclex TRM-V Fly Ash Channel

Repairing Dislocated Highway Shoulders With Curlex

Residential Erosion and Vegetation Establishment with Curlex

Revegetating Waterways with Curlex ECBs

Revisiting a Classic – IDOT Route 6 Project

South Bend Recycles Channel—Recyclex TRM-V

Sustainably Sourced Curlex and Recyclex Products Tackle Residential Erosion Issues

TriNet Recyclex Helps Renovate Water Supply Reservoir

TriNet Recyclex TRM Soil Fill Installation

TriNet Recyclex TRM Vegetated Stormwater Channel

When Unpredictable Weather Calls, Curlex Answers

Case Study Briefs

Curlex All-Natural Curlex Fibers Create a Sediment Control Alternative to Silt Fence 241 kB

Curlex Bloc – Low Energy Shoreline Restoration Applications with Curlex Bloc 2 MB

Curlex Bloc – Natural Filter of Contaminated Stormwater and Construction Runoff

Curlex Bloc – Streambank Restoration with Curlex Bloc 113 kB

Curlex Channel Gets Quick Vegetation Results 1 MB

Curlex Got Results the First Time in this Waterway 94 kB

Curlex I Dormant Seeding with Curlex I QuickGRASS 91 kB

Curlex I QuickGrass All-Natural Curlex Fibers with Instant Curb Appeal

Curlex I Wetland Protection 1MB

Curlex II FibreNet Natural Erosion Control and Revegetation 2 MB

Curlex II FibreNet was the Natural Choice for this Roadside Project 2 MB

Curlex III Erosion Control Blankets – The American Made Alternative to Imported Coconut Erosion Control Blankets

Curlex III – Long-Term Natural Protection for Waterway

Curlex NetFree—Public Park and Shoreline Restoration 2 MB

Curlex QuickGRASS Instant Curb Appeal 127 kB

Curlex -Sediment Control Comparison Curlex® vs. Straw 130 kB

Curlex Sediment Log – All-Natural Curlex Fibers Filter Contaminated Stormwater

Curlex Sediment Log—Naturally Protecting Water Resources from Contaminated Runoff 2 MB

Curlex SiltTRAP is a Proven Alternative to Silt Fence in Sheet Flow Applications 99 kB

Curlex® Sediment Log® Slope Interruption on Challenging Slopes 251 kB

Recyclex TRM-V – Building the Best Vegetated Channels to Protect Fly Ash Landfills 240 kB

Recyclex TRM-V Protected this Waterway—Before and After Vegetation Establishment 130 kB

Recyclex TRMs – Providing Optimal Growth Conditions and Long-Term Vegetation Reinforcement Using Fibers from 100% Recycled Materials 2 MB

SiltTrap – All Natural Fibers Create a Sediment Control Alternative 252 kB

Soil Filling TriNet TRMs and Covering with Curlex II

TriNet Curlex TRM—Turf Reinforcement, Erosion Protection, and Vegetation Establishment 159 kB

TriNet Recyclex TRM – Encouraging Vegetation Protecting Natural Resources

CSI Specifications

AEC Premier Coconut CSI.pdf 436 kB

AEC Premier Coconut FibreNet CSI.pdf 141 kB

AEC Premier Straw/Coconut CSI.pdf 155 kB

AEC Premier Straw/Coconut FibreNet CSI.pdf 140 kB

AEC Premier Straw DN CSI.pdf 152 kB

AEC Premier Straw DN FibreNet CSI.pdf 153 kB

AEC Premier Straw DN QuickMow CSI.pdf 153 kB

AEC Premier Straw SN CSI.pdf 155 kB

AEC Premier Straw SN FibreNet CSI.pdf 153 kB

AEC Premier Straw SN QuickMow CSI.pdf 156 kB

AEC Premier Straw Wattles CSI.pdf 130 kB

Bindex BFM CSI.pdf 148 kB

Bindex Wood / Excel Fibermulch II CSI.pdf

Bindex Wood WT / Excel Fibermulch II WT CSI.pdf

Curlex Bloc CSI.pdf 138 kB

Curlex Enforcer CSI.pdf 154 kB

Curlex High Velocity CSI.pdf 430 kB

Curlex High Velocity FibreNet CSI.pdf 139 kB

Curlex I CL CSI.pdf 159 kB

Curlex I CL QuickMow CSI.pdf 159 kB

Curlex I CSI.pdf 156 kB

Curlex I FibreNet CSI.pdf 158 kB

Curlex I QuickMow CSI.pdf 159 kB

Curlex II (.98) CSI.pdf 155 kB

Curlex II .98 QuickMow CSI.pdf 155 kB

Curlex II CL CSI.pdf 157 kB

Curlex II CL QuickMow CSI.pdf 158 kB

Curlex II CSI.pdf 157 kB

Curlex II FibreNet CSI.pdf 158 kB

Curlex II QuickMow CSI.pdf 158 kB

Curlex III CSI.pdf 157 kB

Curlex III FibreNet CSI.pdf 144 kB

Curlex NetFree CSI.pdf 154 kB

Curlex Sediment Log CSI.pdf 141 kB

Curlex Sediment Log Bio CSI 279 kb

Curlex SFW CSI.pdf

Curlex SFW Bio CSI.pdf

Recyclex CSI.pdf 154 kB

Recyclex TRM – V CSI.pdf 150 kB

TriNet Coconut TRM CSI.pdf 170 kB

TriNet Curlex TRM CSI.pdf 295 kB

TriNet Recyclex TRM CSI.pdf 305 kB

TriNet Straw/Coconut TRM CSI.pdf 181 kB

Installation Guidelines

AEC Premier Coconut Installation Guidelines.pdf 111 kB

AEC Premier Straw/Coconut Installation Guidelines.pdf 111 kB

AEC Premier Straw Highway Rolls Installation Guidelines.pdf 107 kB

AEC Premier Straw Installation Guidelines.pdf 107 kB

AEC Premier Straw Wattles Installation Guidelines.pdf 290 kB

Bindex BFM Installation Guidelines.pdf 258 kB

Bindex Wood / Excel Fibermulch II Installation Guidelines.pdf

Bindex Wood WT / Excel Fibermulch II WT Installation Guidelines.pdf

Curlex Blocs Installation Guidelines.pdf 1.18 MB

Curlex Hi-Vis Excelsior Logs Installation Guide.pdf 175 kB

Curlex Installation Guidelines.pdf 112 kB

Curlex NetFree Installation Guidelines.pdf 112 kB

Curlex Roadrunner Installation Guidelines.pdf 113 kB

Curlex Sediment Logs Installation Guidelines.pdf 296 kB

Curlex SFW Installation Guidelines.pdf

Curlex SFW Staking Pattern Guide.pdf

Curlex SiltTRAP Installation Guidelines.pdf 296 kB

Recyclex Installation Guidelines.pdf 112 kB

TriNet Coconut Installation Guidelines.pdf 71 kB

TriNet Curlex Installation Guidelines.pdf 182 kB

TriNet Recyclex Installation Guidelines.pdf 188 kB

TriNet Straw/Coconut Installation Guidelines.pdf 72 kB

Material Specifications and Manufacture Certifications (MSMC)

AEC Premier Coconut FibreNet MSMC.pdf 129 kB

AEC Premier Coconut Highway Rolls MSMC.pdf 137 kB

AEC Premier Coconut MSMC.pdf 136 kB

AEC Premier Straw/Coconut FibreNet MSMC.pdf 129 kB

AEC Premier Straw/Coconut Highway Rolls MSMC.pdf 139 kB

AEC Premier Straw/Coconut MSMC.pdf 136 kB

AEC Premier Straw DN MSMC.pdf 137 kB

AEC Premier Straw FibreNet DN MSMC.pdf 139 kB

AEC Premier Straw FibreNet SN MSMC.pdf 139 kB

AEC Premier Straw Highway Rolls DN MSMC.pdf 137 kB

AEC Premier Straw Highway Rolls SN MSMC.pdf 137 kB

AEC Premier Straw SN MSMC.pdf 137 kB

AEC Premier Straw Wattles NonStandard MSMC.pdf 124 kB

AEC Premier Straw Wattles Standard MSMC.pdf 125 kB

Bindex BFM MSMC.pdf 129 kB

Bindex Wood / Excel Fibermulch II MSMC.pdf

Bindex Wood WT / Excel Fibermulch II WT MSMC.pdf

Curlex Bloc MSMC.pdf 161 kB

Curlex Enforcer MSMC.pdf 133 kB

Curlex Green Savers MSMC.pdf 120 kB

Curlex Hi-Vis Excelsior Logs MSMC.pdf 240 kB

Curlex High Velocity FibreNet MSMC.pdf 127 kB

Curlex High Velocity MSMC.pdf 134 kB

Curlex I CL MSMC.pdf 140 kB

Curlex I CL FibreNet MSMC.pdf 261 kB

Curlex I FibreNet MSMC.pdf 138 kB

Curlex I MSMC.pdf 134 kB

Curlex II (.98) MSMC.pdf 134 kB

Curlex II FibreNet MSMC.pdf 138 kB

Curlex II CL FibreNet MSMC.pdf 266 kB

Curlex II CL MSMC.pdf 140 kB

Curlex II MSMC.pdf 134 kB

Curlex III FibreNet MSMC.pdf 125 kB

Curlex III MSMC.pdf 134 kB

Curlex NetFree MSMC.pdf 133 kB

Curlex RoadRunner DN MSMC.pdf 134 kB

Curlex RoadRunner SN MSMC.pdf 134 kB

Curlex Sediment Log NonStandard Bio MSMC.pdf 127 kB

Curlex Sediment Log NonStandard MSMC.pdf 127 kB

Curlex Sediment Log Standard Bio MSMC.pdf 126 kB

Curlex Sediment Log Standard MSMC.pdf 126 kB

Curlex SFW MSMC.pdf

Curlex SiltTrap MSMC.pdf 124 kB

E-Staple MSMC.pdf 120 kB

QuickGRASS PRO MSMC.pdf 136 kB

Recyclex MSMC.pdf 137 kB

Recyclex TRM – V MSMC.pdf 137 kB

Steel Wire Staples MSMC.pdf 113 kB

TriNet Coconut TRM MSMC.pdf 96 kB

TriNet Curlex TRM MSMC.pdf 238 kB

TriNet Recyclex TRM MSMC.pdf 275 kB

TriNet Straw/Coconut TRM MSMC.pdf 97 kB

Wooden Stakes MSMC.pdf 113 kB

Miscellaneous Documents

AEC Anchor & Staple Brochure.pdf 4 mB

AEC Channel Application Guide – Metric.pdf 154 kB

AEC Channel Application Guide – U.S..pdf 170 kB

AEC LEED Brochure.pdf 135 kB

AEC Product Line Overview.pdf 441 kB

AEC Recommended Sediment Device Slope Spacing – Metric.pdf 69.9 kB

AEC Recommended Sediment Device Slope Spacing – U.S..pdf 69.8 kB

AEC Slope Application Guide.pdf 103 kB

AEC Twist Pin Brochure.pdf 2.3mB

American Excelsior Erosion Control Brochure.pdf 4 MB

ASTM D7322 Press Release.pdf 67 kB

Bindex BFM Fish Toxicity Report.pdf 115 kB

Channel Application Guide Increasing Shear Stress 4 MB

Completely unrolling RECPs by AEC.pdf 186 kB

Curlex Bloc ASTM D5141 Results 286kB

Curlex Bloc Press Release.pdf 99.6 kB

Curlex CL Press Release.pdf 22.1 kB

Curlex Features and Benefits.pdf 662 kB

Curlex Sediment Log and AEC Wattle Design Values.pdf 41.2 kB

EarthStabilizer PD.pdf 801 kB

E-Stapler Release.pdf 181 kB

EcoSustainable Products by AEC.pdf 345 kB

Erosion Control March_April 2014 Page 14.pdf 1.56 MB

PipelineBrochure_2013_016.pdf 1.28 MB

RECP Cross Reference Guide.pdf 47.7 kB

Sediment Log Channel Spacing – Metric.pdf 44.1 kB

Sediment Log Channel Spacing – U.S..pdf 35.9 kB

Slope Application Guide Increasing Gradient 2 MB

TriNet Recyclex Landfill Application.pdf 7 MB

YouTube Video List

Product Data Sheets

AEC Premier Coconut FibreNet PDS.pdf 121 kB

AEC Premier Coconut PDS.pdf 375 kB

AEC Premier Straw/Coconut FibreNet PDS.pdf 123 kB

AEC Premier Straw/Coconut PDS.pdf 121 kB

AEC Premier Straw Highway Rolls DN PDS.pdf 347 kB

AEC Premier Straw Highway Rolls SN PDS.pdf 120 kB

AEC Premier Straw DN FibreNet PDS.pdf 134 kB

AEC Premier Straw DN PDS.pdf 117 kB

AEC Premier Straw SN FibreNet PDS.pdf 134 kB

AEC Premier Straw SN PDS.pdf 121 kB

Curlex Bloc PDS.pdf 215kB

Curlex I CL PDS.pdf123 kB

Curlex I FibreNet PDS.pdf 135 kB

Curlex I PDS.pdf 123 kB

Curlex II .98 PDS.pdf 124 kB

Curlex II CL PDS.pdf 123 kB

Curlex II FibreNet PDS.pdf 137 kB

Curlex II PDS.pdf 123 kB

Curlex III FibreNet PDS.pdf 112 kB

Curlex III PDS.pdf 123 kB

Curlex Enforcer PDS.pdf 106 kB

Curlex High Velocity PDS.pdf 377 kB

Curlex High Velocity FibreNet PDS.pdf 229 kB

Curlex NetFree PDS.pdf 117 kB

Curlex RoadRunner DN PDS.pdf 122 kB

Curlex RoadRunner SN PDS.pdf 122 kB

Curlex Sediment Log PDS.pdf 218kB

Curlex Sediment Log Bio PDS.pdf 218kB

Curlex SFW PDS.pdf

Curlex SFW PDS Bio.pdf

Curlex SiltTRAP DN PDS.pdf 112 kB

Curlex SiltTRAP SN PDS.pdf 112 kB

Recyclex PDS.pdf 122 kB

Recyclex TRM – V PDS.pdf 122 kB

TriNet Coconut TRM PDS.pdf 84 kB

TriNet Curlex TRM PDS.pdf 237 kB

TriNet Recyclex TRM PDS.pdf 219 kB

TriNet Straw/Coconut TRM PDS.pdf 82 kB

Product Description

AEC Premier Coconut and Straw/Coconut PD.pdf 815 kB

AEC Premier Straw PD.pdf 15 mB

AEC Premier Straw Wattles PD.pdf 1.01 MB

Bindex BFM PD.pdf 308 kB

Bindex Wood / Excel Fibermulch II PD.pdf

Curlex Blankets PD.pdf 964 kB

Curlex Bloc PD.pdf 1.38 MB

Curlex CL PD.pdf 880 kB

Curlex Green Savers PD.pdf 501 kB

Curlex Heavy Duty Blankets PD.pdf 1.01 MB

Curlex Hi-Vis Excelsior Logs PD.pdf 1 MB

Curlex NetFree PD.pdf 771 kB

Curlex RoadRunner PD.pdf 947 kB

Curlex Sediment Log PD.pdf 855 kB

Curlex Sediment Log Bio PD.pdf 986 kB

Curlex SFW PD.pdf

Curlex SFW Bio PD.pdf

Curlex Septic Blankets PD.pdf 479 kB

Curlex SiltTRAP PD.pdf 899 kB

EarthStabilizer PD.pdf 801 kB

E-Staples and E-Stapler PD.pdf 790 kB

ErosionWorks Design Software PD.pdf 1.01 MB

QuickGRASS PRO.pdf 774 kB

Recyclex TRM and TRMV PD.pdf 1.06 MB

TriNet Family of TRMs PD.pdf 1 MB

SDS

AEC Premier Coconut and Highway rolls SDS.pdf

AEC Premier Coconut FibreNet SDS.pdf

AEC Premier Straw SN and DN FibreNet SDS.pdf

AEC Premier Straw SN, DN, and Highway Rolls SDS.pdf

AEC Premier Straw Wattle SDS.pdf

AEC Premier Straw/Coconut and Highway rolls SDS.pdf

AEC Premier Straw/Coconut FibreNet SDS.pdf

Bindex BFM SDS.pdf

Bindex Wood / Excel Fibermulch II – No TAC SDS.pdf

Bindex Wood WT / Excel Fibermulch II WT SDS.pdf

Curlex Bloc SDS.pdf

Curlex Enforcer SDS.pdf

Curlex Hi-Vis Excelsior Logs SDS.pdf

Curlex High Velocity FibreNet SDS.pdf

Curlex High Velocity SDS.pdf

Curlex I, I CL, II, II CL, III SDS.pdf

Curlex I and II FibreNet SDS.pdf

Curlex III FibreNet SDS.pdf

Curlex NetFree SDS.pdf

Curlex QuickGRASS SDS.pdf

Curlex RoadRunner SDS.pdf

Curlex Sediment Log BIO SDS.pdf

Curlex Sediment Log SDS.pdf

Curlex SFW SDS.pdf

Curlex SFW SDS Bio.pdf

Curlex SiltTRAP SDS.pdf

E-Staple SDS.pdf

QuickGRASS PRO SDS.pdf

Recyclex TRM Recyclex TRM – V SDS.pdf

TriNet Coconut SDS.pdf

TriNet Curlex SDS.pdf

TriNet Recyclex SDS.pdf

TriNet Straw/Coconut SDS.pdf

Wooden Stakes SDS.pdf

Staple and Stake Pattern Guides

AEC Premier Coconut Staple Pattern Guide.pdf 155 kB

AEC Premier Straw/Coconut Staple Pattern Guide.pdf 156 kB

AEC Premier Straw Staple Pattern Guide.pdf 125 kB

AEC Premier Straw Wattle Staking Pattern Guide.pdf 94.1 kB

Curlex CL Staple Pattern Guide.pdf 125 kB

Curlex NetFree Staple Pattern Guide.pdf 161 kB

Curlex Sediment Log Staking Pattern Guide.pdf 55.7 kB

Curlex Sediment Log Staple Pattern Guide.pdf 90.3 kB

Curlex SiltTrap Staple Pattern Guide.pdf 109 kB

Curlex Staple Pattern Guide.pdf 153 kB

Recyclex Staple Pattern Guide.pdf 159 kB

TriNet Coconut Staple Pattern Guide.pdf 487 kB

TriNet Curlex Staple Pattern Guide.pdf 490 kB

TriNet Recyclex Staple Pattern Guide.pdf 494 kB

TriNet Straw/Coconut Staple Pattern Guide.pdf 487 kB

Tech Notes

All Excelsior Blankets Are Not Created Equal.pdf 865 kB

Biodegradable Blanket Without Netting Material – Curlex NetFree.pdf 465 kB

Curlex QuickGRASS Blankets Tech Note.pdf 854 kB

E-Staple Unique Biodegradable Turf Staple.pdf 1.17 MB

Evaluation of Erosion Control Product Properties, Performance Capabilities, and Failure Mechanisms.pdf 4.99MB

Mechanical (blankets) vs Chemical (mulches) Bonding.pdf 6.06 MB

Recyclex TRM From Plastic Bottles.pdf 1.18 MB

Shear Stress.pdf 967 kB

Tech Tip Videos

Comparison of ECB Fibers.wmv 7 MB

Curlex Bloc Installation.wmv 6.93 MB

Curlex Easy Unrolling Guide.wmv 6.8 MB

Curlex Fibers Remove Oil From Water.wmv 5.54 MB

Curlex Natural Mechanical Functions.wmv 3.57 MB

Curlex Sediment Log vs Straw Wattle Flow Rate Video.wmv 27 MB

E-Staple Tech Tip.wmv 4.69 MB

Ecologically Friendly Curlex Fibers.wmv 3.4 MB

Trench Method A.wmv 6.73 MB

Trench Method B.wmv 6.92 MB

Technical Papers

(1997 IECA) Design… Technology Test Laboratory.pdf 460 kB

(1998 IECA) Research… Facilities (CERFs).PDF 240 kB

(1998 IECA) Research… Facilities (REFs).PDF 194 kB

(2001 ASCE) Quantifying… Best Management Practices.pdf 1.91 MB

(2002 IECA) Use… Event-by-Event Basis.pdf 358 kB

(2003 IECA) Determining… (BMPs).pdf 115 kB

(2003 IECA) Quantitative… Under Simulated Rainfall.pdf 95.7 kB

(2004 IECA) ErosionLab… Control Industry.pdf 142 kB

(2004 IECA) Estimating… Runoff From Hillslopes.pdf 109 kB

(2004 StormCon) Which… For Slope Protection.pdf 360 kB

(2005 IECA) Introduction… Facility (SCF).pdf 1.31 MB

(2006 StormCon) Testing… Perimeter Control BMPs.pdf 1.4 MB

40 Years of Slope Surface Stabilization.pdf 1 MB

Blown Straw vs. Erosion Control Blankets.pdf 1.22 MB

Coir Products – A Different Kind of Invasive.pdf 457 kB

Curlex Bloc Natural Filters.pdf 4.45 MB

Fly Ash Filtration Using Curlex Blocs.pdf 2 MB

Fly Ash Filtration Using Curlex Sediment Logs.pdf 2 MB

Soil Temperature… in a Desert Ecosystem.pdf 367 kB

Videos

YouTube Video List 294 kB

48_hr_Vegetated_Recyclex_2_am.WMV 1.08 MB

ASTM_D7208_Curlex_Sediment_Log_Testing.wmv 1.23 MB

ASTM_D6459_AEC_Premier_Straw_Test.WMV 1.34 MB

ASTM_D6459_Bare_Soil_Control.wmv 1.86 MB

ASTM_D6459_Curlex_II_Test.WMV 654 kB

ASTM_D6459_Curlex_NetFree.wmv 711 kB

ASTM_D6460_Bare_Soil_Testing.wmv 859 kB

ASTM_D6460_Curlex_I_Test.WMV 605 kB

ASTM_D6460_Curlex_I_Vertical_Wall.wmv 733 kB

ASTM_D6460_Curlex_III_Test.wmv 1.24 MB

ASTM_D6460_NetFree_Test.WMV 1.69 MB

ASTM_D6460_Vegetated_Recyclex_Test.wmv 1.65 MB

Bindex_BFM_Application_First_Pass.wmv 2.23 MB

Bindex_BFM_Mixing_in_Hydroseeder.wmv 741 kB

Curlex_RoadRunner.wmv 985 kB

Curlex_Sediment_Log_Perimeter_Control_Testing.wmv 1.76 MB

Does_Your_TRM_Float_During_Hydraulic_Events.wmv 3.9 MB

ErosionLab_Education.wmv 963 kB

Hands_on_education.wmv 3.07 MB

FAQs

What Is Curlex®?

Curlex is perhaps the most studied, and unique erosion and sediment control fiber today. Curlex comes in many forms for erosion control, sediment control, and revegetation purposes. The most common form comes in roll form, which may be referred to as Rolled Erosion Control Products (RECPs), Erosion Control Blankets (ECBs), or simply blankets. Curlex also comes in tubular Curlex Sediment Log® form. Our latest innovation of Curlex is the Curlex® Bloc. The key to any version of Curlex is the Curlex fiber itself, which leads to superior performance-based results. Unlike other fibers, Curlex fibers have natural mechanical functions. Curlex excelsior products promote ideal growing conditions for seed, while simultaneously providing protection from wind and water erosion. Curlex is engineered specifically to yield ideal performance results with its curled interlocking soft barbed fibers that create a strong, multi-directional fiber matrix. Beyond superior erosion control, sediment control, and revegetation, Curlex fibers also remove oil from water. Read more about the Features and Benefits of Curlex. The word “Curlex” has become synonymous with various erosion control materials, but don’t be fooled by imitators. There is only one Curlex.

Why is Curlex® SUPER?

Sustainable Curlex® fibers offer Unique characteristics, delivering high Performance through their expertly Engineered features. American Excelsior Company offers the support and Resources you need to make your project a success.

SUSTAINABLE – Curlex® is made from renewable, sustainably harvested Great Lakes Aspen, native to North America. The trees used to produce Curlex® fibers are harvested near our manufacturing facility in Rice Lake, WI, which minimizes our carbon footprint. Aspen trees are a fast-growing species and are self-propagating. Aspen stands at various stages of their life cycle are key to several wildlife species such as grouse and elk. The largest living organism in the United States is a stand of aspen in the western U.S.

UNIQUE – Curled, barbed Curlex® fibers expand and contract during hydraulic events, digging into the subgrade and forming a “Velcro-like” connection. Unlike blankets made with straw fibers, properly installed naturally seed-free Curlex® blankets will not float. Curlex® fibers slowly release moisture into the soil, creating a “greenhouse effect” that sup ports vegetation establishment. Curlex® blankets are also available with a non-toxic green pigment that can be added to the fibers for an aesthetically pleasing, finished appearance.

PERFORMANCE – Erosion and sediment control products made with Curlex® fibers reduce job site risk and help you stay in compliance. Doing it right the first time means lower lifetime project costs and higher profits. All performance-based Curlex® products are quantified by large-scale ASTM testing and have decades of proven field success. In addition to holding soil in place and fostering ideal seedbed conditions for vegetation, Curlex® fibers effectively remove polynuclear aromatic hydrocarbons (PAHs) and heavy metals from contaminated stormwater.

ENGINEERED – Engineered and designed for erosion and sediment control products, Curlex® fibers create a bond so strong that netting is not required as proven by the industry’s most environmentally friendly, 100% biodegradable Curlex® NetFree™. Only sourcing Aspen fibers means that Curlex® fibers do not contain pitch or resin, so they produce naturally clean fibers. Unlike straw, an agricultural byproduct, Curlex® fibers are designed to provide a superior roughness factor (Manning’s n) to slow water velocity and resist shear forces.

RESOURCES – Curlex® is manufactured by American Excelsior Company®, which has been in business since 1888. Our team of experts on erosion and sediment control, stormwater, and revegetation applications is here to help. Curlex® is backed by the industry’s largest privately-owned test facility – ErosionLab®. We provide excellent service anywhere in the U.S. with our multiple manufacturing plants, warehouse sites, and extensive distribution network. This ensures that technical assistance and our products are always close at hand.

Where Do Renewable Curlex® Fibers Come From?

Engineered Curlex® fibers are made from renewable Great Lakes Aspen trees. All raw materials for Curlex® are purchased from members of sustainable forestry programs. The raw material is engineered into specific cuts of Curlex® fibers that have been designed specifically for erosion control, sediment control, and revegetation benefits.

Responsibly Sourced, Environmentally Friendly, and Sustainable

What Is Excelsior?

Excelsior is shaved wood fibers. Excelsior is a Latin word meaning “always upward.” However, American Excelsior’s has a unique way of curling the fibers with small “barbs” which allows the stands to cling to one another and other objects such as soil when used for erosion control applications. Some excelsior may not contain these features so be sure to ask for “Curlex®” when quality is important.

What Does ECB Stand For?

ECB stands for Erosion Control Blanket.

What are Some Basic Differences Between Blankets and Mulch Products?

Water flows across the tops of blankets because the physical strength provided by the mechanically stitched bonded products are designed to hold together when water flows over them. However, mulch options (hydraulic and dry) that rely on chemical bonds are designed to mainly absorb precipitation because they don’t have enough physical strength to hold together when water flows over them. That is a main reason why we see blow outs when concentrated flow occurs over mulches. Failures with mulch products are also common when the water holding capacity of mulches and/or soil is exceeded on slopes (the mulch and/or soil slump away after an unstable condition is created by the heavy, saturated mulch and/or soil on the surface). High water holding capacity is a property that is intentionally encouraged by some mulch product designs, even though it can lead to slip planes and mass wasting, which is a roadside safety concern and typically leads to environmental contamination. Any perceived monetary savings are quickly lost when having to mobilize multiple times to reapply product to address failures. Doing it right the first time with the proper Curlex®, Recyclex®, and/or TriNet® engineered solution commonly saves everyone time and money. Click below for more information regarding differences between the mechanical bonds of blankets and the chemical bonds of mulch products:

Mechanical (blankets) vs Chemical (mulches) Bonding.pdf

Evaluation of Erosion Control Product Properties, Performance Capabilities, and Failure Mechanisms.pdf

Does The Type Of Degradable Fiber Within The Matrix Of An Erosion Control Blanket (ECB) Make A Difference?

The type of degradable fiber within the matrix of an ECB can mean the difference between a successful application and a failure.

What Is The Difference Between An Erosion Control Blanket (ECB) And A Turf Reinforcement Mat (TRM)?

ECBs are temporary products that are designed to provide erosion control and hasten vegetation establishment. ECBs are used in applications where the resultant vegetation alone will be able to withstand design hydraulic forces. TRMs are long-term solutions that provide erosion control and hasten vegetation establishment, but they also provide long-term reinforcement to the vegetation. TRMs are typically used in applications where the resultant vegetation alone will not be able to withstand design hydraulic forces.

What Does TRM Stand For?

TRM stands for Turf Reinforcement Mat.

What Is The Difference Between Stem Reinforcement And Root Reinforcement By Turf Reinforcement Mats (TRMs)?

Stem reinforcement occurs when vegetation grows up through TRMs so the stems are reinforced by the TRM. Root reinforcement occurs when vegetation grows down into TRMs so the root mass is reinforced by the TRM. Typically, stem reinforcement results from stand alone applications (seed is applied to soil then TRM is rolled over the seed) and root reinforcement occurs from soil fill applications (TRM is rolled out, soil is placed on top of the TRM, soil-filled TRM is seeded, entire system is covered with a degradable Curlex® Erosion Control Blanket (ECB)). American Excelsior Company does not require soil filling with any of our TRMs, but occasionally Designers specify the soil fill installation method.

Do American Excelsior Company Turf Reinforcement Mats (TRMs) Have To Be Soil Filled?

American Excelsior Company does not require soil filling with any of our TRMs, but occasionally Designers specify the soil fill installation method.

What Is Recyclex®?

Recyclex® is a family of performance based environmentally friendly Turf Reinforcement Mats (TRMs). Recyclex® fibers are made from 100% recycled materials – such as soda bottles. Recyclex® TRM products are commonly used towards LEED® Credit(s) 4.1/4.2 amongst other credits. Our LEED® Brochure provides more information regarding potential credit contributions. Recyclex® TRM is arguably the most tested TRM ever. Recyclex® products provide superior performance capabilities for slope and channelized flow applications. Unique Recyclex® products do not float in water. Amazingly, several TRMs on the market today do float in water, which can lead to erosion during hydraulic events.

What Is QuickGRASS®?

QuickGRASS® is a Rolled Erosion Control Product (RECP) option manufactured by American Excelsior Company that is pigmented green. QuickGRASS® RECPs are green in color, which presents a finished, vegetated look until seeds germinate and plants replace the biodegradable matrix of the Curlex® product.

What Is FibreNet™?

FibreNet™ is netting used on American Excelsior Company Erosion Control Blankets (ECBs) that is a biodegradable jute netting option.

Does Curlex® NetFree™ Really Contain No Netting Material?

Curlex® NetFree™ contains biodegradable Curlex® fibers and biodegradable thread material. To our knowledge, Curlex® NetFree™ remains the only biodegradable Erosion Control Blanket (ECB) that does not contain netting material. Curlex® NetFree™ has become a very popular product of choice.

Where Do Straw Fibers Come From?

Straw fiber is an agricultural by-product. After the grain, such as wheat, has been harvested from the plant the stem of the plant is cut. The straw stems are baled then brought to an Erosion Control Blanket (ECB) manufacturing facility where they are “busted” apart before being distributed into an ECB. No engineering goes into straw fibers so their erosion control, sediment control, and revegetation capabilities are limited as compared to Curlex® fibers.

What Is QuickMOW™?

QuickMOW™ is netting used on American Excelsior Company Erosion Control Blankets (ECBs) that is color coded white. QuickMOW™ netting is a rapid degrading netting option.

Why Is NatureZone™ Netting Used On Curlex Erosion Control Blankets (ECBs) Better For The Environment?

Curlex® I CL, II CL, I, II, I .98, & II .98 products are available with environmentally friendly NatureZone™ Netting. NatureZone™ netting contains the industry’s largest net openings, which have been proven effective at minimizing potential entrapments. Other ECBs available (straw, straw/coconut, coconut, etc.) have to use netting with smaller openings sizes otherwise the shorter fibers would fall out of the product. Unique Curlex® fibers cling and barb together, which allows net openings to be very large and environmentally friendly. Unlike other fibers, Curlex® does not need netting to hold it together as is evident with Curlex® NetFree™.

Where Do Coconut/Coir Fibers Come From?

Coir is fiber that comes from the husk of a coconut. No engineering goes into coconut fibers so their erosion control, sediment control, and revegetation capabilities are limited as compared to Curlex® fibers. Coconuts do not naturally grow well in North America, thus coir products are commonly from South Asian countries such as Sri Lanka, India, Pakistan, Bangladesh, Bhutan, Nepal, Maldives, Afghanistan, and Iran. The majority of coir imports into the U.S. come from southern India and Sri Lanka. Read more about potential concerns regarding imported coir based products.

What is American Excelsior Company Doing for the Environment?

- AEC is providing a full line of natural, wildlife-friendly biodegradable Erosion Control Blankets (ECBs). There are no harmful chemicals, binders, crosslinkers or dyes containing toxic malachite green in our ECBs. Our industry-leading Curlex fibers within our ECBs are renewable, sustainable, and responsibly sourced. American Excelsior Company’s full line of Curlex® FibreNet™ ECBs are made with no plastic components.

- AEC is providing fully natural Curlex® Sediment Log® and Curlex® SiltTRAP™ options to help eliminate over 36 pounds of plastic per acre of perimeter control. Biodegradable options from American Excelsior Company can eliminate over 36 pounds of plastic per acre of perimeter control (over 1,640 sixteen-ounce plastic water bottles) in appropriate applications when used in place of 2.1 oz/yd2 silt fence fabric. Note: Be sure to always verify the requirements of each application before substituting any products.

- AEC is providing Turf Reinforcement Mats (TRMs) with fibers from 100% post-consumer recycled goods. Recyclex® TRM family products help keep plastic out of landfills while providing high levels of erosion control and vegetation reinforcement. Proper TRM installations result in the product becoming part of the landscape. Benefits of cost-effective TRMs and vegetated channels over rock rip rap and other hard armors are plentiful.

- AEC is providing Hydraulic Erosion Control Products (HECPs) without toxic malachite green in their tracer dyes. Some specifiers prohibit the use of toxic malachite green based on research because it puts organisms, fish, other wildlife, soil resources, and water resources at unnecessary risk when safer alternatives are available. Certified documentation from the manufacturer of tracer dyes (not the HECP manufacturer) shall be required confirming that the dye material does not contain any toxic malachite green.

- AEC is offering Hydraulic Erosion Control Products (HECPs) in paper bags to eliminate over 310 pounds of plastic per load. A typical truckload of HECPs in plastic bags contains around 310 pounds of plastic packaging waste (over 14,200 sixteen-ounce plastic water bottles)!

Do Most Erosion Control Blankets (ECBs) Contain Seed?

No, most ECBs do not contain seed. Preseeded blankets typically work well only for local or site-specific applications. For example, ideal species in the Southwestern U.S. would likely be different than ideal species in the Northwestern U.S. Matching the proper seed mixture to a site is a very important component of successful erosion control applications using any ECB. Thus, American Excelsior Company defaults to local seed experts to determine the seed mixture that should be used in conjunction with our products.

How Do I Know Which Product To Use For My Project?

All American Excelsior Company products have performance ratings for slope applications and channel applications on their Material Specifications and Manufacturer’s Certification (MSMC), Product Data Sheet (PDS), and CSI Long Specification that are located in the Technical Support Library. Our free erosion design and analysis software, ErosionWorks®, recommends the right product for the right application based on project-specific input parameters provided by the user. Our Product Line Overview lists all of our products and their recommended applications. In addition, please Contact Us at anytime to help determine which product is the best solution for your project requirements.

Where Can I Get Curlex® And Other Products by American Excelsior Company?

Please Contact Us to find out where the best source is for you to get Curlex® and other products by American Excelsior Company. We have manufacturing locations, distribution partners and retail outlets all across the country.

Contact

We believe in personal and professional attention to our customers and that is why during business hours, we have intelligent, enthusiastic, living human beings answering the phone. If you tell them what you want, they will either provide you with the information you need or will direct you to someone who can.

Customer Service: 1.800.777.7645 — CCS@Americanexcelsior.com

Kurt Kelsey: Division Director

Craig Shultz: Business Development Manager – cshultz@americanexcelsior.com

Darryl Childers: 817.946.9857 — dchilders@curlex.com — TX

Harvey Dickson: 908.329.0343 — hdickson@curlex.com — CT, DE, MA, MD, ME, NH, NJ, NY, PA, RI, VA, VT, ON, QC, NL, NB, PE, NS

Kevin Doll: 815.768.5866 — kdoll@curlex.com — IL, IN, KS, KY, MI, MO, OH, WV

Jon Healy: 612.819.9567 — jhealy@americanexcelsior.com — IA, MN, MT, ND, NE, SD, WI, BC, YT, NT, NU, AB, SK, MB

Jeff King: 940.367.0940 — jking@curlex.com — AR, AZ, CA, CO, ID, LA, NM, NV, OK, OR, TX, UT, WA, WY

Eric Marsal: 770.231.5914 — emarsal@curlex.com — AL, FL, GA, MS, NC, SC, TN

ErosionWorks®

ErosionLab®